How to pick a compressor lubricant

- Check your compressor type

- Check the manufacturer’s recommendations

- Weigh synthetic vs. standard air compressor oil

- Consider alternative oils, if needed

Just like cars need motor oils and other lubricants to hit optimal performance, so do air compressors.

Picking and using the right compressor lubricants for your machine will benefit you in many ways, including making it more energy-efficient and long-lasting. But, choosing the ideal lubricant for your compressor type, model, and application can be difficult.

Below, we’ll cover how to pick compressor lubricant and some considerations. Read on.

What Is Compressor Lubricant?

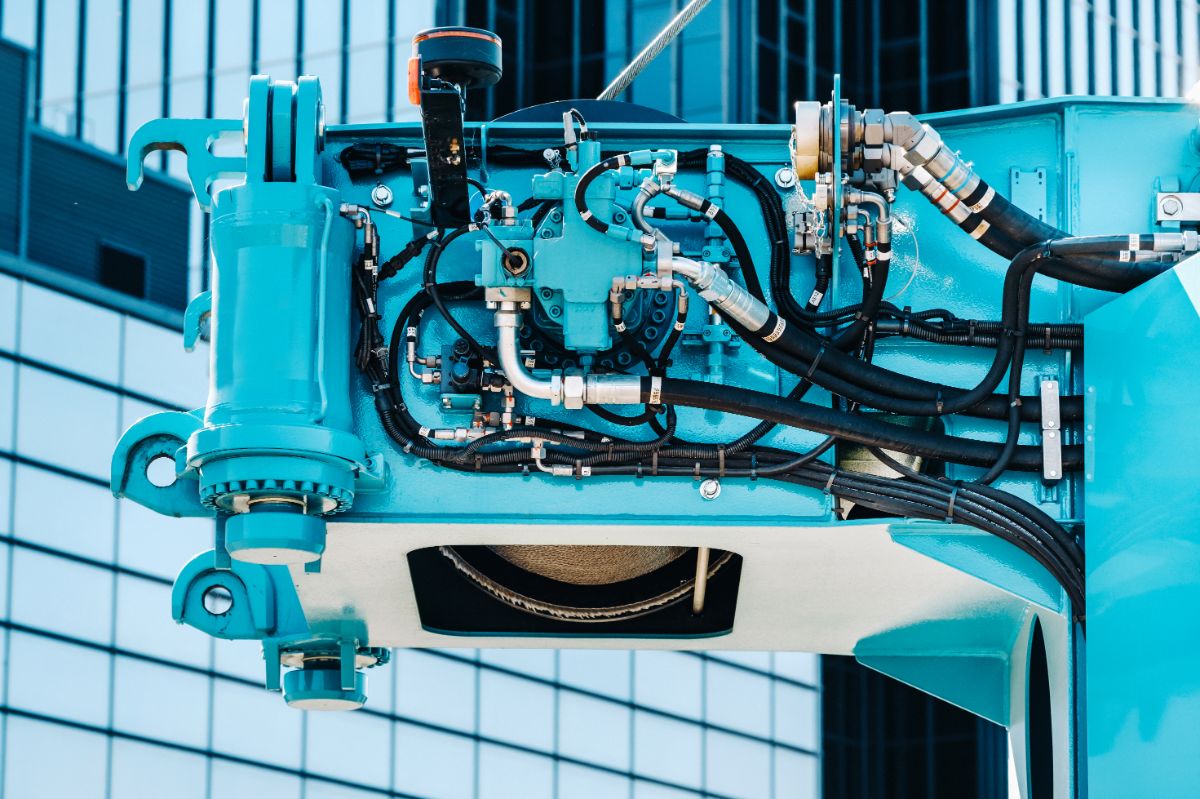

Compressor lubricant is a type of formulation critical for the functioning of a machine. First, it lubricates all the moving parts so that they avoid wear and tear. Second, it acts as a cooling agent inside the machine, carrying heat as it cycles throughout the system. Third, it creates tight seals, eliminating gaps around components like gaskets and o-rings.

These functions help your compressor operate at optimal levels, increasing overall efficiency. Without compressor lubricants, your machine experiences gaps, hot spots, and raw metal-on-metal contact, causing damage.

Aside from these functions, there are other benefits of using the right compressor lubricant for your machine:

- Oxidation resistance — provides a protective coating that delays the oxidation and acid formation process.

- Expanded lifespan — additives in compressor lubricants can protect your compressor and its components for long periods.

- Operability in cold temperatures — some additives allow the compressor lubricant to stay viscous even in cold temperatures.

- Demulsification — other additives improve water separation, which protects compressor components from water and oil emulsions.

- Anti-foaming — Certain additives prevent foam from forming, which increases the capabilities and lifespan of both lubricant and machine.

Now that you understand their purpose, we can cover how to pick the right compressor lubricant.

Check Your Compressor Type

Different types of compressors require different lubrication specifications; your compressor can be a screw-type compressor, a piston-type compressor, or a refrigeration type of compressor.

Before you start looking for compressor lubricants, examine your air compressor brand/make and model. If you’re unsure of what type it is, go through the user manual, which should include information as to the type of model installed on the machine.

Check The Manufacturer’s Recommendations

The best thing to do before picking out an air compressor lubricant is to consult your user manual. This will include compressor maintenance guidelines, specifying what grade and type of oil should be used. They may also mention which blends can work on your air compressor.

You’ll always want to follow the manufacturer’s specifications as they’re part of the warranty guidelines. Using a non-specified oil lubricant could void the warranty on your equipment.

This is especially true if your compressor is used for commercial applications, and is working with specialized gasses or refrigerants. As it works with volatile and sensitive substances, the lubricant you’ll need is likely specialized to be non-reactive with such substances.

If your manual does not specify a type of oil, you can consult a qualified lubrication expert like Lubri-Chem. Generally, we will recommend using a standard 20 weight or 30 weight compressor oil. But, as always, we will take extra steps to examine your machine, its needs, and its application before recommending a compressor lubricant for you.

Weigh Synthetic Vs. Standard Air Compressor Oil

The two basic types of air compressor lubricants are standard and synthetic. Each one has distinct characteristics to keep in mind while making your selection.

Standard compressor lubricants are made with a mineral oil base. They’re less expensive compared to synthetic lubricants more suitable for light- to medium-duty applications. Standard lubricants are recommended for non-industrial compressors, or for applications that don’t run compressors continuously.

Synthetic compressor lubricants are made with a synthetic base. They’re more refined than the standard type, but also more expensive.

Choose synthetic lubricants if you’re using a compressor for professional purposes (industrial or commercial), or if you run the compressor continuously. This type of lubricant tends to run more quietly and smoothly and has a higher overall temperature range.

Some models can run just fine with either one — but as always, we recommend following your manufacturer’s guidelines. Typically, they will specify which type to use, with synthetic lubricants being the more common choice.

Consider Alternative Oils, If Needed

We don’t recommend using any other lubricant for your compressor. But, if you’re in a pinch, and need a temporary solution, there are some acceptable alternatives. Note that using any of these may void your machine’s warranty, so try this at your own risk. We also recommend consulting us before making any changes to your lubricants.

Hydraulic oils have many of the same qualities as compressor lubricants, making them an acceptable substitute. However, they tend to have a lower viscosity in colder temperatures, so hydraulic oil works best when temperatures are lower.

Motor oils can also be a suitable substitute. However, some motor oils contain detergents, which can cause excessive carbon buildup in your compressor. Make sure to choose a substitute motor oil without detergents.

Where Can I Get Compressor Lubricants?

The best way to get the right compressor lubricant and ensure the best performance and reliability of your machines is to get in touch with a lubrication expert. On top of manufacturer guidelines, we at Lubri-Chem will be able to evaluate your situation and your machine to find the best lubrication solutions for you.

We carry only top-of-the-line lubricants specially formulated by Shell — the international leader in oil refinement and lubricant products. We offer a wide range of products, so you’re sure to find just the right one for the job!

Key Takeaway

To keep your air compressor operating at its best, you need to know how to pick a compressor lubricant. While this can be a tricky decision to make, Lubri-Chem has got your back. Contact us today and we can help you investigate your options. We can also provide more information on our products, or help you browse the wide selection of lubricants we have available.